Introduktion

Break through the limitations of the original worktable,using swing welding head Any Angle welding, welding seam width adjustable, replace the traditional argon arc welding, Electric welding process, simple operation no need for welding certificate.

Tekniska parametrar

Model.No | DTW-500W | DTW-1000W | DTW-1500W | DTW-2000W |

Operating Mode | Continuous/Modulation | |||

Laser våglängd | ±2% | |||

Power Requirements | 220V | 220V/380V | 220V/380V | 220V/380V |

Machine Power | ≤5KW | ≤7KW | ≤9KW | ≤11KW |

Operating Environment Temperature Range | 15-35 ℃ | |||

Working Environment Humidity Range | <70% No Condensation | |||

Welding Thickness Range | 0.5-0.8MM | |||

Welding Line Requirements | ≤0,5 mm | |||

Svetshastighet | 0-120 mm/s | |||

Maskinstorlek | 1190×1100×650mm | |||

Laser cutting sample

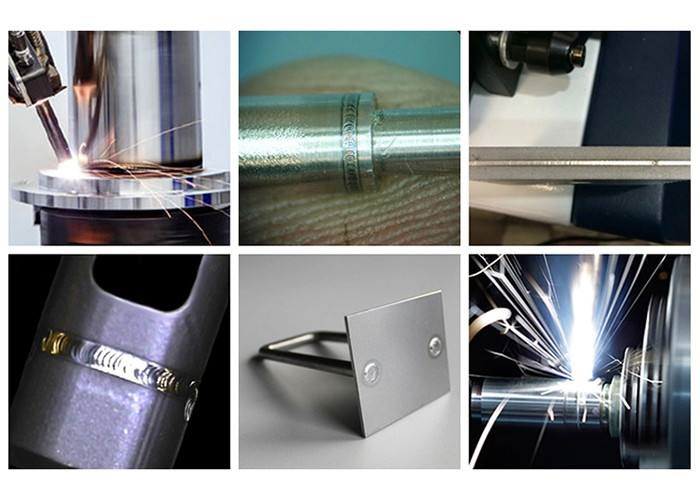

✦Applicable Materials: Leapion laser welding machine Application in Stainless steel, Carbon steel, Aluminum, Copper materials, etc.

Funktioner

Hand-held welding gun operating mode, can be welded to any angle of any part of the work piece.

Hand-held welded head is equipped with 10 m fiber, flexible and convenient can achieve outdoor welding.

Applicable to various complex welds, spot welding of various devices.

Lätt att använda

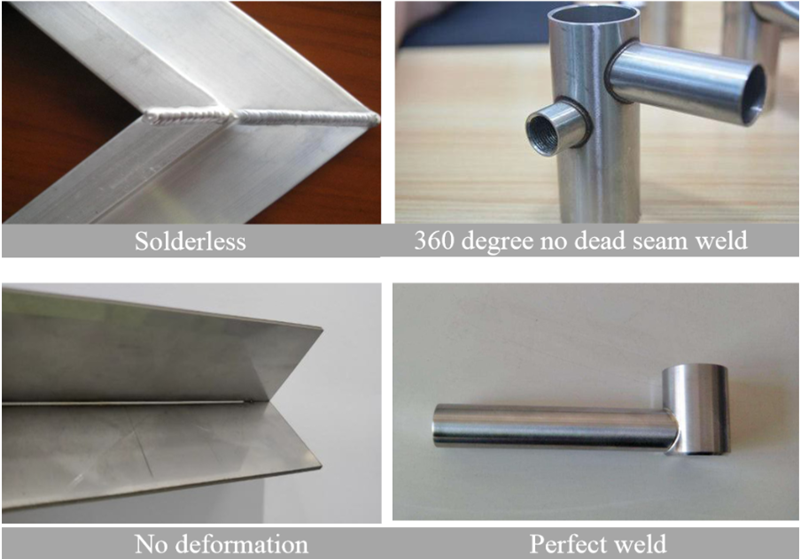

Simple and easy to operate, no deformation of the welding seam, stable laser output to ensure welding consistency, high power density after laser focusing, fast speed, great depth and small deformation, 360-degree micro-welding.

Vacker svetsprocess

Genom att bryta igenom begränsningarna för den ursprungliga arbetsbänken är den lämplig för alla typer av komplexa svetssömmar, och det är lätt att svetsa vilken del av arbetsstycket som helst i vilken vinkel som helst. Den humaniserade designen och teknikuppgraderingen kan svetsa vackra svetssömmar.

Liten kropp, effektiv svetsning

The welding speed of laser welding machine is 3-10 times that of traditional argon arc welding and plasma welding. The welding heat affected area is small, and it will not cause problems such as deformation, blackening, traces on the back of the joint construction, and the welding depth is large, the melting is sufficient, and the welding is firm.

Dubbeldrivet handhållet svänglasersvetshuvud

Det finns 6 svetslägen och flera svetsmunstycken för att möta olika svetsbehov; den har en säkerhetssensorfunktion, som avger en laser efter att ha berört metallen och automatiskt låser ljuset när det tas bort; spiraljitterfunktionen, svetsbredden kan justeras och svetsförmågan förbättras avsevärt.

360° Ingen dödvinkel mikrosvetsning

After the laser beam is focused, a small spot can be obtained, which can be accurately positioned, and is applied to micro and small workpieces that are automatically produced in large quantities. Mainly for the welding of thin-walled materials and precision parts, it can realize spot welding, stitch welding, tailor welding, sealing welding, etc. High aspect ratio, small weld width, small heat aff